Pin con la testa con la testa

Invia richiesta

Clevis pins with head are great because they’re versatile, strong, and cheap. They’re made to handle really strong pulling and pushing forces, so they last a long time even when things are moving a lot. One big plus is they work with lots of different clevis brackets and rod ends, so you can easily add them to systems you already have.

Unlike screws or bolts with threads, clevis pins don’t wear out from spinning or rubbing, which makes the parts they’re in last longer. They come in different materials and coatings,for example, ones that won’t rust in the ocean or light ones for planes to fit different needs. And since you can reuse them, you save money on maintenance and don’t have to stop work as much.

Features

Stainless steel clevis pins with head (like grades 304 or 316) work well in rusty environments because their chromium oxide layers fight corrosion. Marine aluminum pins with anodized coatings stand up to saltwater damage. For really tough conditions,like super high heat,Inconel or Monel alloys don’t oxidize even at 2000°F.

You should check them regularly for pits or color changes to catch problems early. Make sure the clevis ends match the pin material (like using aluminum with stainless steel) to avoid galvanic corrosion. Using lubricants with rust inhibitors also helps them last longer in damp or acidic places.

Customization

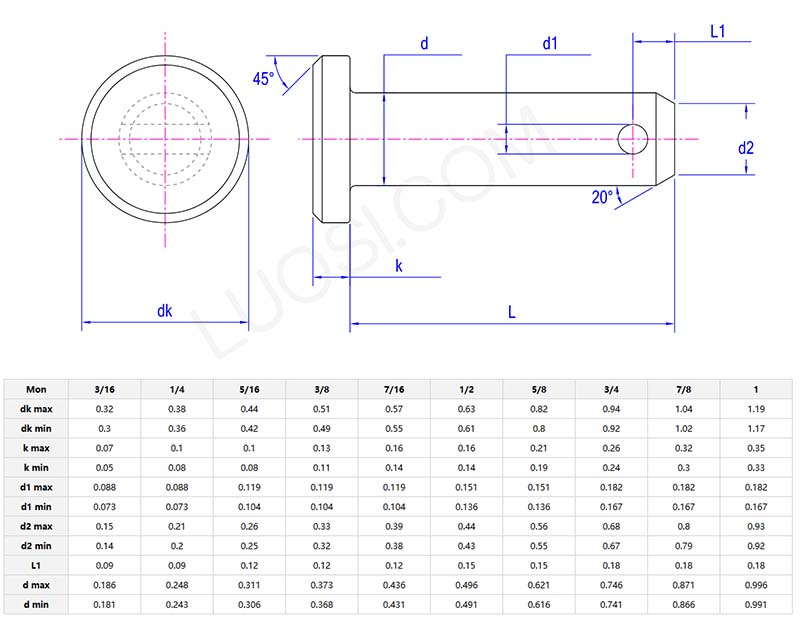

Q: Can you provide clevis pins with head with custom dimensions or tolerances?

A: Yes, we mainly make clevis pins that fit specific needs,like non-standard sizes, lengths, or thread types. We use CNC machines to cut them precisely, keeping tight tolerances (like ±0.01mm) and can be well connected and fixed to hydraulic systems or automotive parts.

Just send us your CAD drawings or a sample, and our engineers will adjust the design to work well and save costs. If you order in bulk, we’ll include free reports that check the sizes to make sure they meet ISO/DIN/ANSI standards.